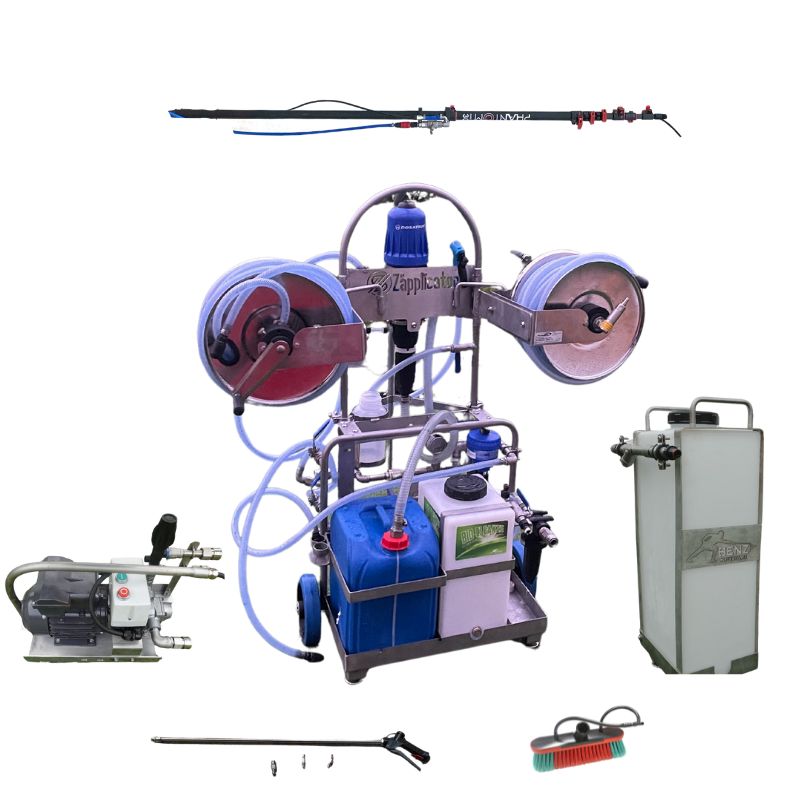

Makes the dilution and delivery of softwash chemical solutions easier, safer and more efficient than traditional systems

A Soft Washing Equipment Solution

The Benz Zapplicator is our flagship softwash application system, designed and developed by Ben as the foundation of the entire Benz application range.

It is the original plug-and-spray system that led to the creation of the Lightning Zap, Mini-Zap and Zap-Pack. If you want the full professional system — not an entry-level unit — this is it.

The Zapplicator delivers safer, more accurate chemical dilution without batch mixing or pumping chemicals through engines.

Built for professional soft washing. Built for serious contractors.

Chosen By

- Small, medium and large cleaning contractors

- Facility management companies

- Property management companies

- Private estates and institutions

This is not a starter unit.

It is designed as long-term professional infrastructure.

Watch the Zapplicator in Action

What Makes It Different

The Benz Zapplicator is simple, easy to use and engineered for real-world work. It delivers:

- Accurate chemical dilution

- Precision delivery to the treatment surface

- Quiet operation without petrol or diesel pumps

- Modular mobility for transport and servicing

- Multi-operator capability from one frame

Your investment includes personalised training and ongoing phone and email support from our team.

Quiet Soft Washing

Because it does not rely on a petrol or diesel pump, the Zapplicator is particularly suited to noise-sensitive areas.

This provides a genuine commercial advantage when tendering for residential, institutional or public contracts where engine noise is a concern.

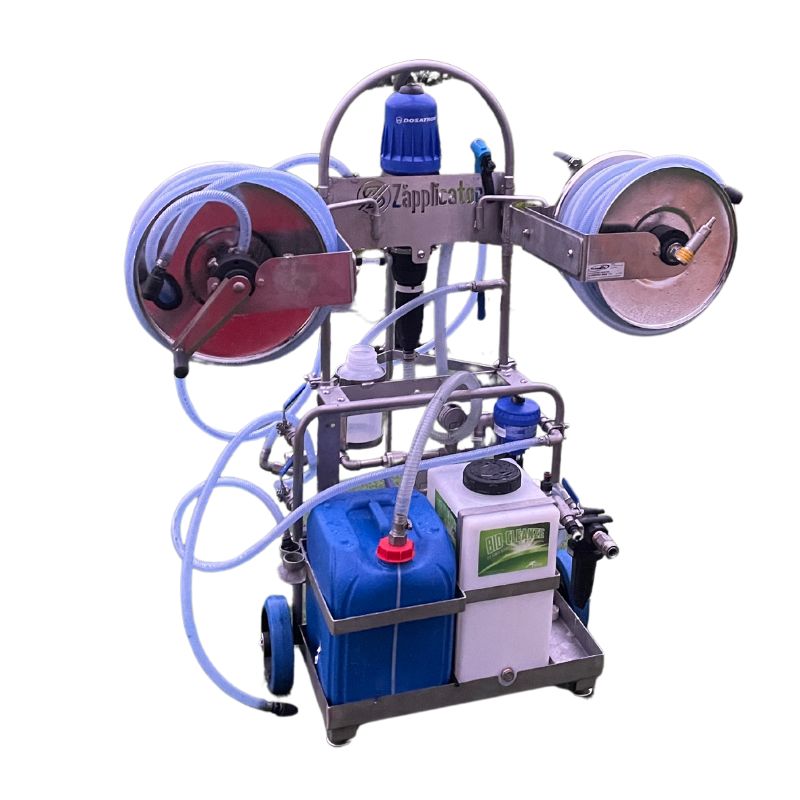

Modular Mobility

The Zapplicator separates into manageable modules for easy transportation and one-person lifting.

- Move it in and out of a light van

- Wheel it closer to the treatment area

- Set it up on site and free your vehicle for other work

It is designed to work with you — not tie up your van.

Flexible Functionality

Add a whip hose or additional hose reels to increase operational reach.

The Zapplicator allows you to:

- Apply Benz Lightning Cleanze

- Apply Benz Bio Cleanze

- Spray two different treatments simultaneously

- Rinse treated areas

- Pre- and post-drench plant life

- Support ancillary equipment when required

One operator can treat a roof while another rinses adjacent areas — all from a single system.

No batch mixing.

No pumping chemicals through engines.

Powered by Water – True Plug ’n Spray

Built around water-driven chemical injectors, the Zapplicator connects directly to a suitable water supply.

With approximately 5 litres per minute at 40 psi, you can operate in plug-and-spray mode on:

- Roofs

- Render

- Patios

- Driveways

- Commercial surfaces

Domestic water supplies typically range from 30–80 psi and 5–10 LPM, which is usually sufficient.

If pressure drops below 30 psi or 5 LPM, a booster pump may be required.

Add the Benz MaxFlow Booster Pump (When Required)

For low-pressure sites, pair the Zapplicator with the Benz MaxFlow — our purpose-built 220V booster pump.

- Maintains consistent flow and pressure

- Ensures stable chemical dosing

- Doubles as a quiet rinsing pump for gutters, fascia and delicate finishes

- Available with or without buffer tank and fittings

In commercial and industrial settings, a booster is often not required due to higher water pressure.

Built for Professional Workflows

- Spray both Benz biocides at varying flow rates

- Run multi-operator setups from one unit

- Reduce reliance on petrol-powered pumps

- Lower trip hazards compared to van-mounted systems

- Operate without electrical components in water-powered mode

- Protect pumps from chemical exposure in booster mode

A hinged, swivelling and detachable hose reel allows deployment in any direction.

It fits inside a light van alongside window cleaning or pressure washing equipment.

It can operate from tap water, de-ionised water, or a van-mounted tank supply.

Engineered for Durability

- Portable

- Corrosion resistant

- Serviceable

- Safe for employees

- Adjustable for low and high flow rates

- Capable of running without electricity in standard mode

At the centre of the system is the Benz FrameFlo manifold designed to simplify plumbing and protect dosing units and gauges.

Key build features include:

- Stainless steel mounting brackets

- 304-grade stainless pressure regulating valves

- Oil-filled stainless pressure gauges

- Heavy-duty tubular protective frame

- Pressure-tested welds using dye penetrant testing

This is professional-grade equipment built for long-term use.

Why Contractors Invest in the Zapplicator

- Eliminates daily batch mixing

- Improves dilution accuracy

- Reduces chemical handling risk

- Increases team efficiency

- Reduces downtime

- Protects pumps from chemical exposure

- Supports scalable, multi-operator workflows

For established contractors, the Zapplicator becomes infrastructure — not equipment.

Worldwide Delivery

We ship the Zapplicator and all Benz softwash equipment worldwide.

Contact us for shipping rates to your country.

Your financial investment includes free personalised training and ongoing support.